Organizations that make use of data center infrastructure, including server, storage, and network equipment, must consider the best way to maintain these assets, to ensure the highest level of performance. Equipment failure can impact operations and profitability, so keeping downtime to an absolute minimum is a top priority for companies where IT plays an important role.

At the same time, managers understandably want to find the most affordable solutions to optimize their IT budget. Given these realities, companies have two major options when it comes to IT support and maintenance: OEM or TPM contracts. Next, we’ll look at what they are and their differences.

What is OEM support?

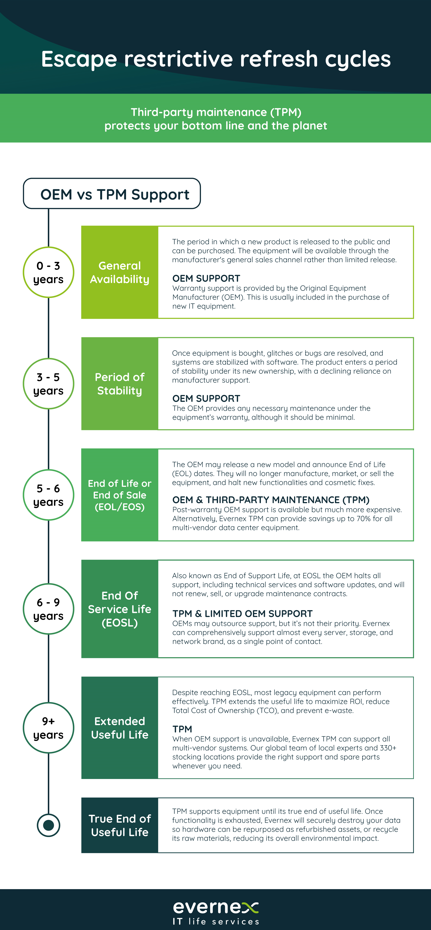

OEM (Original Equipment Manufacturer) support refers to technical support and other services provided by a company that manufactures and sells equipment. OEM support can include software updates, troubleshooting assistance, repair or replacement of defective parts, and access to training materials. This type of support is generally available for up to 6 years after the equipment were released. However, once new generation products become available the OEM would typically halt support and flag the equipment as end-of-life.

What is TPM support?

TPM, short for Third-Party Maintenance, is the practice of outsourcing the maintenance, repair and support of IT equipment and systems to an external vendor, rather than maintaining it in-house or through the OEM. This can include hardware maintenance and other IT-related services like troubleshooting and technical support. Unlike the OEM who mostly supports only the equipment they manufacture, a TPM provider has multi-vendor capabilities.

Benefits of choosing Third-Party Maintenance

- Cost

First of all, TPM provides considerable savings compared with OEMs. In fact, third-party maintenance can be up to 70% cheaper. - Extending the life of IT assets

Original Equipment Manufacturers are incentivized to provoke premature refresh cycles, as their priority is to sell new machines. Third-party maintenance providers, meanwhile, extend the life of existing equipment beyond their original warranty end date or their established EOSL (End of Service Life), giving the customer more control over their replacement strategy. - Flexibility in contract term

TPM contracts typically offer greater flexibility than those of an original equipment manufacturer, which usually don’t offer contracts of less than a year in length, for instance. - Leverage against an OEM quote

The savings offered by TPM providers with their maintenance contracts can be used to negotiate better terms with an OEM. Faced with losing a client’s business, an OEM might be willing to match a TPM offer in some or all aspects, giving you greater leverage in your negotiations. - Superior service

While OEM’s service thousands of clients at a time, TPM maintenance providers usually provide more personal attention and a faster, more responsive service that can be customized according to your organization’s specific needs. - Multi-vendor support

Many current data centers are equipped with infrastructure from different companies. Being brand-agnostic, third-party management providers offer the benefit of becoming a single point of contact for support and maintenance even when your equipment comes from multiple manufacturers, considerably simplifying and streamlining the process. - A smaller carbon footprint

Last but not least, third-party maintenance, by extending the life of existing equipment, prevents the manufacture of new machines and the emissions involved, which are substantial: up to 80% of a computer’s lifetime greenhouse gas emissions are produced during its manufacturing process. For organizations, this results in improved sustainability scores, an increasingly important metric for today’s CIOs.

A hybrid approach

For many organizations, then, the benefits of switching to a third-party maintenance contract are considerable. If a company is sceptical about such a change, it can also take, as Gartner suggests, a hybrid approach, combining TPM and OEM contracts.

To find out more about the process and costs of switching to a third-party maintenance contract, contact the support team at Evernex.